Das unternehmen triebel Waffenwerkzeuge GmbH

Wir sind Europas führender Hersteller von Spezialwerkzeugen für Waffenwerkstätten – Triebel Waffenwerkzeuge GmbH. Unsere Expertise im Bereich Waffenwerkzeuge für Polizei-, Jagd- und Sportwaffen, kombiniert mit über 70 Jahren Erfahrung, stellt uns an die Spitze in Sachen Qualität und Zuverlässigkeit.

Unsere Präzisionswerkzeuge sind weltweit anerkannt und leisten einen wesentlichen Beitrag zur inneren Sicherheit und waidgerechten Jagd. Als spezialisierter Ausrüster für Beschussämter, Waffenhersteller und Büchsenmacher verhelfen wir Sportschützen zum gelungenen Wettkampf und Sicherheitsbehörden zu erfolgreichen Einsätzen auf höchstem Niveau.

Erfahren Sie mehr über unsere langjährige Tradition und unser Engagement für exzellente Waffenwerkzeuge. Gegründet von Rudi Triebel, einem Meister im Büchsenmacherhandwerk, hat sich das Unternehmen seit 1948 in der Branche etabliert.

Mit einem umfangreichen Maschinenpark und einem DIN ISO 9001 zertifizierten Qualitätsmanagementsystem bietet Triebel hochwertige Produkte und Dienstleistungen. Der Fokus liegt auf Innovation, Qualität und Kundenzufriedenheit, was sich in der langjährigen Geschichte und dem modernen, kundenorientierten Ansatz widerspiegelt.

Über uns

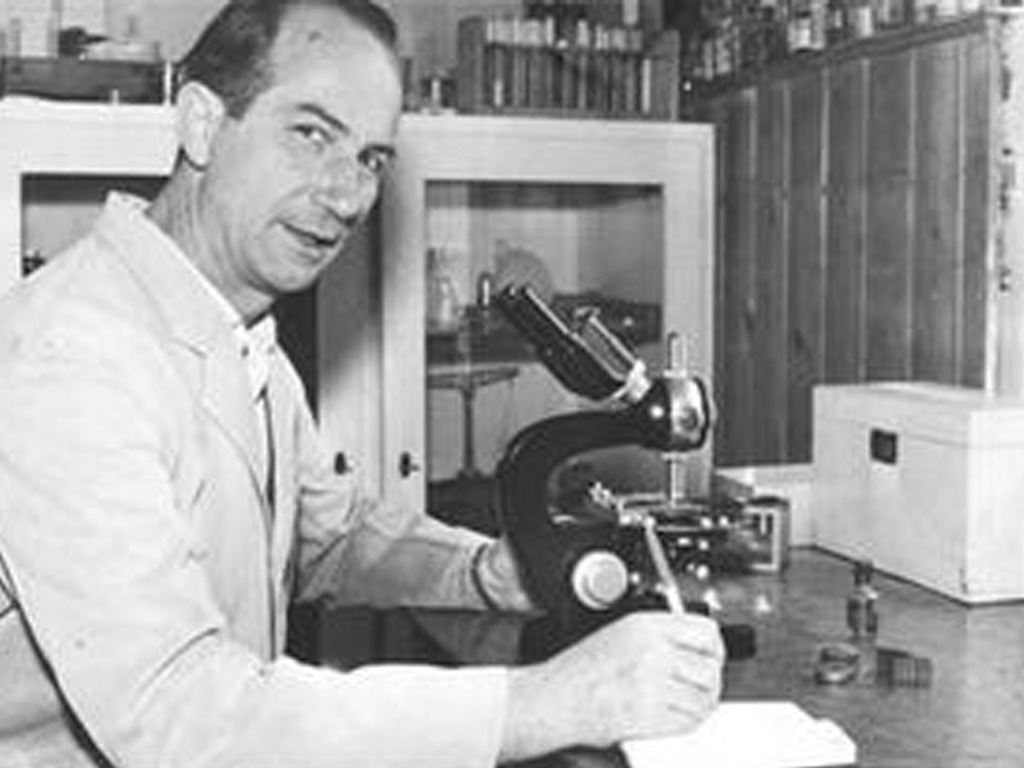

Firmengründer Rudi Triebel, geboren in Suhl, erlernte traditionsgemäß das Büchsenmacherhandwerk.

Sein Lehrmeister war Edgar Hübner, den er sehr verehrte. Als Gesellenstück baute Rudi Triebel eine Anson-Doppelflinte.

Seine Meisterprüfung legte er bereits 1942 erfolgreich ab. Nach dem II. Weltkrieg, den er bis auf ein paar Blessuren gut überstand arbeitete er in der Waffenwerkstatt seines Vaters Robert Triebel, welcher schon seit 1935 in Kaufbeuren, „Am Breiten Bach“ ein Fachgeschäft für Waffen, Munition und Angelbedarf führte.

Historie

In der Kemptener Str. 73 in Kaufbeuren, richtete er sich später einen eigenen Arbeitsraum ein. Dort konnte er die ersten Maschinen aufstellen und mit Hilfe eines Mitarbeiters, einem Bekannten aus der Militärzeit, Teile für Waffen, Zielfernrohrmontagen und die ersten Werkzeuge für Patronenlager selbst herstellen. Die Gewerbeanmeldung erfolgte 1948.

Der Grundstein für die Firma Triebel Waffenwerkzeuge war somit gelegt. Neben seiner Arbeit war Rudi Triebel auch für die Innung tätig und bekleidete viele Jahre das Amt des Lehrlingswartes und auch des Innungsmeisters. Zahlreiche Ballistikkurse für die Lehrlinge und die Absolventen des Meisterkurses brachten ihm den Ruf eines hervorragenden Fachmannes ein, der auch im Ausland sehr geschätzt wurde.

Durch die Veröffentlichung der „Maßblätter für Patronen- und Patronenlager“, die u.a. aufgrund seiner Tätigkeit im Beschussrat entstanden, erfuhr der Name Triebel eine neue Bedeutung. Immer wenn Fragen bezüglich der Abmessungen von Patronenlagern auftraten hieß es: frag bei Triebel nach. Nach kurzer, schwerer Krankheit starb Rudi Triebel am 30.5.1984 in Kaufbeuren.

Daraufhin übernahm der heutige Geschäftsführer Jürgen Triebel, kurz nach dem, Bestehen der Meisterprüfung (damals als bester bayerischer Prüfling) die technische Leitung der Firma Triebel. Mit den damals zur Verfügung stehenden Mitteln wurde eine neue Universal-Werkzeugschleifmaschine angeschafft, wodurch sich neue Möglichkeiten in der Produktion boten.

Mit den bald schon obligatorischen Ausstellungen auf der größten Fachmesse für Waffen und Zubehör, der IWA in Nürnberg, wurden schnell Kontakte in der gesamten Branche geknüpft. Laufende Investitionen in sämtlichen Unternehmensbereichen, der Ausbau des Exports, sowie im Jahre 2004 die längst fällige Expansion mit dem Umzug in das heutige Firmengebäude in Stöttwang und die Einführung eines maßgeschneiderten, ISO zertifizierten Qualitätsmanagementsystems haben die Firma Triebel Waffenwerkzeuge GmbH zu dem gemacht was sie heute ist:

Ein modernes, qualitätsbewusstes und kundenorientiertes Unternehmen mit einem hervorragenden Ruf, auch über die Europäischen Grenzen hinaus.

Unser Maschinenpark

Leistungsspektrum Lohnfertigung

Unser Know-How und unsere Maschinenkapazitäten stehen natürlich auch zur Fertigung von Lohnaufträgen zur Verfügung. Von der Materialbeschaffung bis hin zur Laserbeschriftung können wir auch Ihre Produkte fertigen.

Unser Leistungsspektrum umfasst z.B. folgende Möglichkeiten:

Studer S21 – CNC universal Rundschleifmaschine

Baujahr 2013

Zubehör:

Innenschleifspindel, Papierbandfilter, umfangreiche Software, diverse Schleifscheiben und Aufnahmen

Studer S20 – Konventionelle Rundschleifmaschine

Generalüberholt 2018

Zubehör:

Papierbandfilter, Absauganlage, digitale Steuerung

Studer OF – Konventionelle Rundschleifmaschine

Geometrisch / mechanisch überholt 2013

Zubehör:

Kühlmittelanlage mit Absetzbecken, Absauganlage

Haas, Trossingen – Multigrind AF – CNC Profischleifmaschine

Baujahr 2004

Zubehör:

Spindelkühlung, Absaugung für Schleifen in Öl, umfangreiche Software, diverse Schleifscheiben und Flansche, Schleifscheibenwechsler

Haas, Trossingen – Multigrind AF – CNC Profischleifmaschine

Baujahr 2011 – Werkstüberholung 2018

Zubehör:

Spindelkühlung, Absaugung für Schleifen in Öl, umfangreiche Software, diverse Schleifscheiben und Flansche, Abrichteinheit, Schleifscheibenwechsler

Traub TNL 32 – CNC Kurz-Langdrehautomat

Baujahr 2013Zubehör:

Stangenlader 3m, Softwarepaket WinFlexIPS, Absaugung für Betrieb in Öl, umfangreiche Werkzeugausstattung inklusive diverse AGW

Traub TNL 18 – CNC Kurz-Langdrehautomat

Baujahr 2011

Zubehör:

Kurzstangenlader, Softwarepaket WinFlexIPS, Absaugung für Betrieb in Öl, umfangreiche Werkzeugausstattung inkl. diverse AGW

Spinner TC 600-65 SMCY – CNC Drehmaschine

Baujahr 2015

Zubehör:

Stangelader Servo-Load 80 (1500 mm), Haupt- und Gegenspindel, Y-Achse, umfangreiche Software, diverse AGW und hochwertige Werkzeuge, automatischer

Index G200 Compact – CNC Drehmaschine

Baujahr 2000

Zubehör:

Stangengreifer, umfangreiche Spannmittel und Werkzeugausrüstung, Absaugung.

Trotec Speedmarker 700 / 20 Watt Faserlaser 50 Hz – Beschriftungslaser

Baujahr 2016 Zubehör: Stangengreifer, umfangreiche Spannmittel und Werkzeugausrüstung, Absaugung.

Schneider Bad Kreuznach – SKM 250 – CNC Koordinaten-Messsystem

Auf- / Nachgerüstet 2007

Zubehör:

Softwarepaket, durchgehende Kalibriernachweise über gesamten Lebenslauf nach Herstellervorgaben.

Zoller Smile 400 – CNC Mess- und Werkzeugeinstellgerät

Auf- / Nachgerüstet 2007

Zubehör:

Umfangreiche intuitive Software, Etikettendrucker, Taumelausgleich, diverse hochwertige Spannmittel

Allgemeine Werkstattausrüstung

Zubehör: Teilreiniger BioCircle, beheiztes Ultraschallbad BioCircle, mehrere konventionelle Drehmaschinen, Ständerbohrmaschine, Lagerregale, Stangensäge

Mess- und Prüfmittel

Zubehör:

Vollsortiment an kalibrierten Gewinderingen und Dornen, digitale Bügelmessschrauben, Innenmessschrauben, digitale Messchieber, Sonderformlehren.

Qualitätsmangement

Der Nutzen eines Unternehmens für seine Kunden, die Qualität von Produkten und Dienstleistungen, effiziente interne Abläufe, eine gesunde wirtschaftliche Situation – all das hängt entscheidend davon ab, wie Prozesse im Unternehmen sichergestellt und gelebt werden. Vor diesem Hintergrund gewinnt ein Managementsystem immer größere Bedeutung.

Zu Ihrem Nutzen haben wir deshalb unser Unternehmen nach DIN ISO 9001 zertifizieren lassen. Durch die Anwendung unseres maßgeschneiderten, zertifizierten Managementsystems sind wir in der Lage, auf alle erdenklichen Situationen schnell und angemessen reagieren zu können.